General installation / installer tips

General installation / installer tips

1. Water tank size:

The required amount of hot water per person ranges from 30 to 40 liters per shower on average.

When choosing a boiler, the size of the apartment and the hot water pipes that are installed in the house and/or from the roof must be taken into account.

- A family of 2 needs a water tank with a volume of 80 liters.

- A family of 3–4 needs a water tank with a volume of 120 liters.

- A family of 4–5 needs a water tank with a volume of 150 liters.

- For a family of more than 5 it is recommended to install a 200 liter water tank.

2. Panel type:

a. The type of panel will be determined according to the boiler volume and the heat output of the panel

b. Installation method (vertical / horizontal)

c. Open / closed system

d. Installation area – in areas prone to extreme climatic conditions (frost)

it is preferable to purchase iron (Schedule) panels.

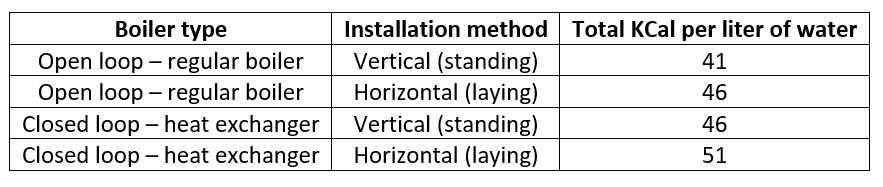

3. Required heat outputs:

Table for calculating the daily heat output required from a standard system.

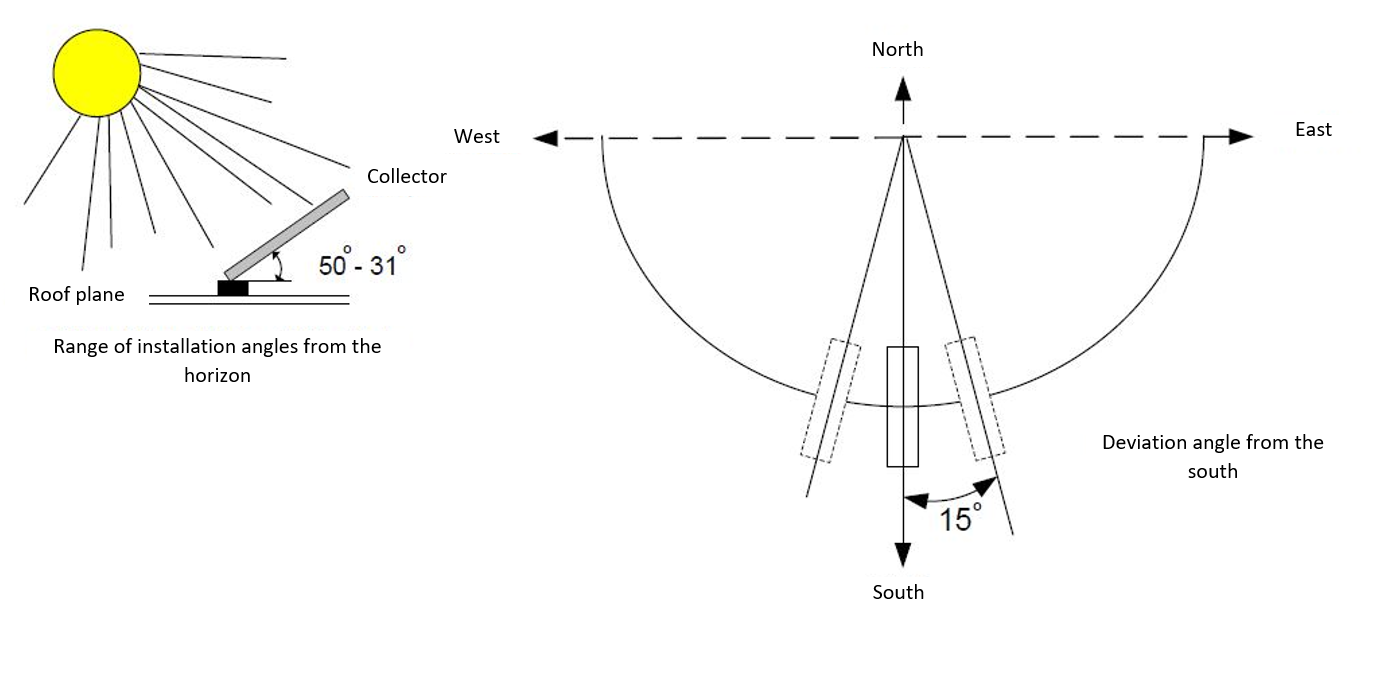

4. Panel positioning

The panels should be installed facing south as much as possible –

A deviation of up to 15° to the east or west is permitted without increasing the output.

Place the panels facing the horizon at an angle of 31° – 50° without increasing output.

If this is not possible, the total output must be increased as mentioned in the table in Section 5.

Refer to the illustration below

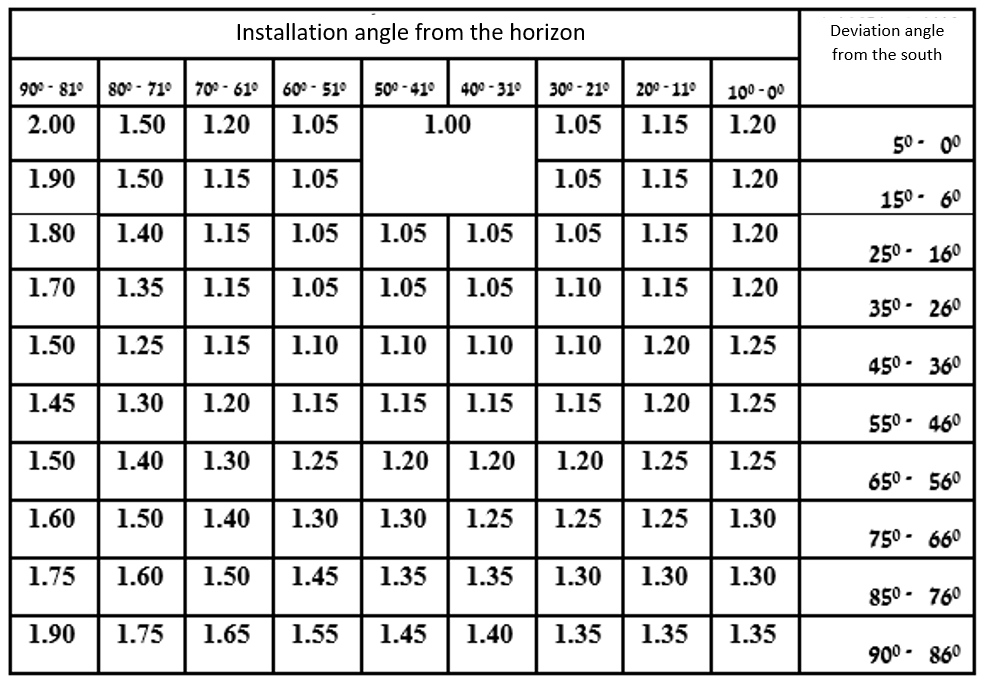

5. When placing panels in deviation from the south and/or at angles of placement towards the horizon that exceed the permitted ranges, the daily output of the panels must be increased—by adding panels or installing larger panels—according to the correction coefficient from the table in Israeli Standard 579 Part 4 below:

For example: An open-system boiler in a standing position requires an output of 41 kcal per liter according to the table in Section 3.

The following is the calculation for a 150 liter boiler.

150 liters x 41 kcal = 6,150 kcal for a system placed within the permitted range of angles.

If there is a deviation from the south of 28° to the west or east and the angle to the horizon is 65°

Look up the table and find the required coefficient.

The first column shows the ‘deviation angles from the south’ so the figure should be cross-referenced with the figure in the column of the angle towards the horizon.

In this example we get a coefficient of 1.15 as highlighted in the table, and the calculation for the required output will therefore be as follows: 6,150 x 1.15 kcal = 7,072 kcal

6. Shading on the panels:

The panels should be placed where no shadow will be cast on them from any direction—in an amount that could significantly reduce the required daily output from the system.

Do not place the panels where there is a concern that a building, tree, or any other object may cast a shadow on the panels, except for an antenna, chimney, or narrow pole.

7. Water tank:

The water tank will be equipped with a safety valve, a non-return valve, and an electric disconnect switch, and will be installed in a place

that will allow easy access for maintenance purposes.

8. Pipes:

Inlet – A cold water pipe from the network to the boiler

Outlet – A hot water pipe from the boiler to the house

Return pipe from the panel to the water tank – A cold water pipe from the boiler to the bottom of the panel

Feed pipe from the water tank to the panel – A hot water pipe from the top of the panel to the top of the boiler

The total length of the return and feed pipes together

shall not exceed 15 meters in a normal installation,

shall not exceed 8 meters in a low silhouette installation.

8.1. Pipe material:

Do not use a plastic pipe to connect the panels to the boiler.

It is permissible to use a plastic pipe for the inlet pipe and the outlet pipe.

8.2 Permitted pipes diameter:

Pipe fittings shall be made of metal only.

When the outlet pipe is made of plastic, a section of metal pipe 50 cm long and with

a diameter of ¾ of an inch must be connected without insulation between the plastic pipe and the water tank.

(If a temperature mixer is installed, this pipe is not needed.)

Plastic pipes located on the roof must be protected from mechanical damage.

All pipes except the inlet pipe shall be wrapped in thermal insulation.

The insulation material shall be resistant to the pipe temperatures, solar radiation, moisture, and other natural hazards.

The insulation thickness for piping outside the building shall be at least 19 mm and for piping inside the building shall be at least 13 mm.

9. Anchoring:

When installing a system on the roof, the roof’s ability to carry its weight must be taken into account.

The panels should be tied to the boiler stand and the boiler to its stand with the help of galvanized twisted wire.

In any case, the anchoring method of the system on a flat roof or a sloped roof will prevent the system from moving in any direction.

The piping connecting the boiler to the panels should not be considered as a means of anchoring.

The system installer bears sole responsibility for the stability and anchoring of the installation, even if the installer has replaced only one component of the system (boiler or panel).

10. Upon installation completion:

Check that there is no damage to the roof’s waterproofing that will cause water to enter the building.

The impermeability of the system should be checked.

Turn on the electrical backup and check that there is power consumption in the main clock.

These tips should not be used as a substitute for the official Israeli standard 579 Part 4.

In case of any problem or if help is required, contact the factory’s technical manager.